step‑by‑Step Process Explained: Mold Inspection in Satellite Beach from AC Condensation

Satellite Beach’s hot, humid climate — especially in summer — places heavy demand on air conditioning systems. As AC units cool indoor air, moisture condenses on coils and collects in drain pans and condensate lines. Normally this water should exit harmlessly through drainage pipes, but when condensation isn’t properly routed or drained, moisture accumulates and creates ideal conditions for mold growth.

Mold spores are everywhere in the environment — but they only flourish on damp surfaces. Condensation that’s allowed to pool in attics, crawl spaces, ducts, or under insulation gives spores the moisture they need to germinate. That’s why AC condensation issues are one of the most common hidden causes of indoor mold in Florida homes. Recognizing and inspecting for this early helps protect your home’s structure and indoor air quality.

🌡️ Why AC Condensation Leads to Mold in Satellite Beach

Before we dive into the inspection process, it’s important to understand how and why AC systems can create moisture problems:

💦 AC Systems and Condensation

When warm, humid air from indoors passes over cold AC coils, moisture in the air condenses — just like water beads on a cold glass. That condensation should flow down into a drip pan and then out through a drain line. Problems arise when:

- The drip pan is clogged or rusted

- Condensate drain lines are blocked by debris

- Insulation around ducts or coils is missing or wet

- Airflow is poor, causing excess condensation

- Outdoor humidity is high, slowing drying and evaporation

In Satellite Beach’s dense, humid summer air, these issues become more frequent, especially in older systems.

🧪 Why Mold Grows

Mold needs:

- Moisture (from condensation)

- Organic material (dust, paper, wood, drywall)

- Warm temperatures (typical in Florida)

Where AC systems create standing or slow‑draining moisture, mold spores find their ideal environment. Because the problem often starts behind walls or inside HVAC systems, it can go unnoticed until the infestation is advanced.

🔍 Mold Inspection Step‑by‑Step

A professional mold inspection is not a simple “look around and guess.” It’s a systematic evaluation that uses tools and techniques to uncover visible and hidden mold issues — especially those stemming from AC condensation.

1. Initial Contact & Pre‑Inspection Planning

📍 What Happens

- You describe your concerns to the inspector: musty smells, allergy symptoms, visible stains, or recent AC problems.

- The inspector asks about:

- History of AC maintenance

- Frequency of condensation or clogging

- Recent water intrusion events

- Rooms or areas where symptoms are strongest

This information helps the inspector tailor the plan and bring the right tools.

💡 Why It Matters

AC‑related mold often hides in places you can’t see (attic, ductwork, behind drywall). Knowing where the AC components are located helps focus the inspection.

2. Visual Walk‑Through of Affected Areas

The inspector begins with a systematic visual assessment. Typical areas examined include:

- Around AC units, drip pans, and condensate lines

- Air vents and return ducts

- Ceilings and walls near AC runs

- Attics and crawl spaces where HVAC components exist

- Baseboards and flooring near AC output

They look for:

- Visible mold or staining

- Discoloration on walls, ceilings, or insulation

- Rust, corrosion, or damp spots on AC equipment

- Water stains or peeling paint

This step helps identify obvious problems and potential sources.

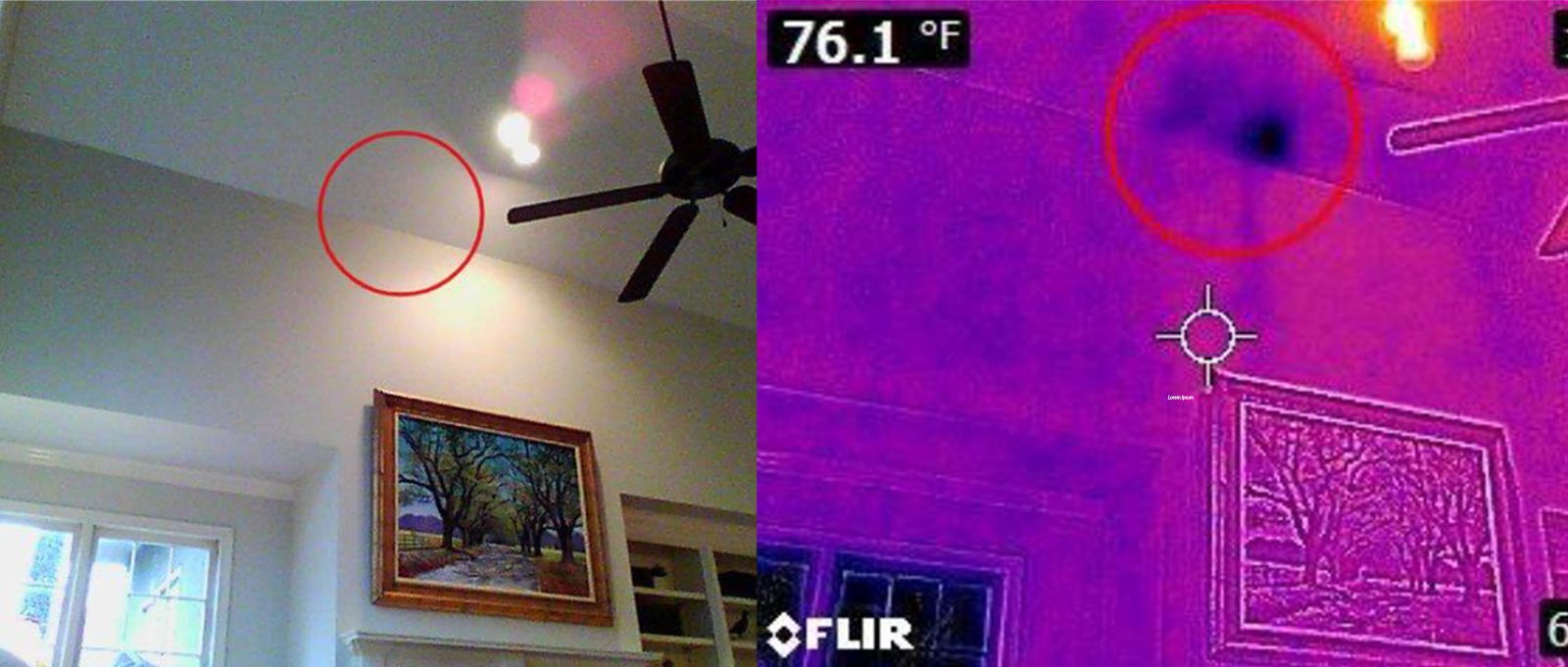

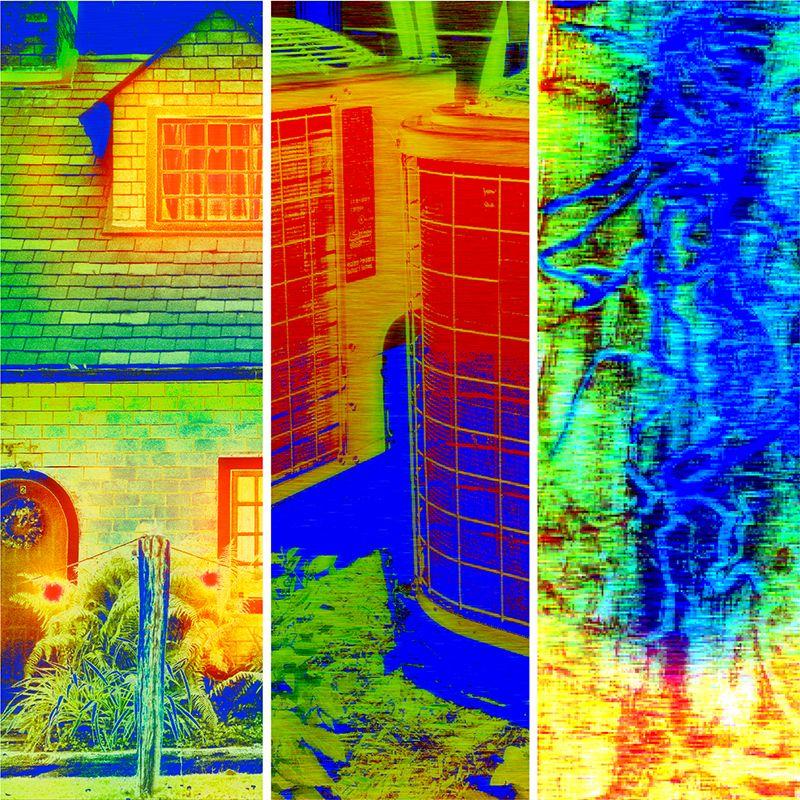

3. Thermal Imaging Scanning

Thermal imaging (infrared scanning) helps inspectors detect hidden moisture behind walls, ceilings, and floors. Moisture cools materials differently than dry areas, so infrared cameras reveal temperature anomalies that indicate:

- Amorphous patches of moisture

- Cool areas where condensate has dampened structures

- Hidden condensation pockets in crawl spaces and attics

🔧 Why This Is Important

Moisture caused by AC condensation doesn’t always leave visible signs early on. Thermal imaging screens large areas quickly and pinpoints where moisture has been trapped — even if it’s not yet visible to the naked eye.

4. Moisture Meter & Hygrometer Testing

After identifying suspect areas, inspectors use precise tools:

🧰 Moisture Meters

- Pin‑type meters penetrate material to measure moisture content

- Pinless meters scan surfaces without damage

These tools quantify how wet materials like drywall, wood, and insulation are in suspected zones.

🌬️ Hygrometers

- Measure relative humidity and dew point in rooms and HVAC spaces

- Identify where humidity is elevated and condensation is likely

High humidity near AC return vents or in attics often correlates with condensation issues.

5. Air Quality & Spore Sampling (Optional But Recommended)

For a deeper assessment, inspectors may take:

- Air samples inside multiple rooms

- Surface tape samples from visible mold

- HVAC duct samples

These are sent to labs that count and identify spore types and concentrations.

📊 How Results Are Interpreted

- Elevated mold spore counts in areas with AC systems suggest moisture problems related to HVAC condensation

- If outdoor spore levels are lower than indoor levels, hidden indoor sources are likely

Lab results help differentiate between normal background mold and a problem that needs remediation.

6. Report & Diagnosis

After testing and inspection, you receive a detailed report that includes:

✔ Areas checked

✔ Moisture readings and infrared images

✔ Air quality/spore analysis results (if taken)

✔ Likely causes of moisture (e.g., AC condensation overflow, clogged drains, insufficient insulation)

✔ Recommended next steps

This report is your roadmap for remediation and repair.

🧠 Interpreting Common AC‑Related Mold Findings

Here are some typical scenarios inspectors see in Satellite Beach homes caused by AC condensation:

✅ Clogged or Slow Condensate Drain

When the condensate line clogs, water backs up into drip pans, overflows, and migrates into ceilings or walls.

❗ Rusty or Deteriorated Drip Pans

Older systems may have drip pans that no longer drain effectively, creating standing water.

⚠️ Poor Insulation Around Ducts

Cold AC ducts in attics can accumulate condensation on the exterior, which then drips into insulation and building material.

🌫️ High Indoor Humidity

Even well‑maintained AC systems can produce excess condensation if overall humidity isn’t controlled — especially when doors and windows stay closed during storms.

🧑🔧 What Happens After Inspection

Once the inspection report confirms mold or moisture sources from AC condensation, the next phase is remediation and correction.

1. Fix the Moisture Source

- Clean and clear condensate drain lines

- Repair or replace drip pans

- Improve insulation around ducts and coils

- Adjust AC settings to reduce humidity load

If the problem is persistent humidity, a dehumidifier may be added to the HVAC system.

2. Professional Mold Remediation

Remediation involves:

- Containment of affected areas

- Removal or cleaning of mold‑infested materials

- HEPA‑filtered air scrubbers to remove spores from the environment

- Sanitization of HVAC ducts and systems if needed

The strategy depends on the severity and location of mold growth.

3. Post‑Remediation Verification

After remediation, a follow‑up inspection — sometimes with sampling — confirms that mold levels are reduced and moisture sources are controlled. This is especially useful if testing was done before remediation.

🛠️ Tips to Prevent AC‑Related Mold in the Future

Preventing mold from AC condensation requires both HVAC maintenance and indoor moisture management:

✔ Regular AC Maintenance

Schedule seasonal checks to clean coils, inspect drip pans, and clear condensate lines.

✔ Use UV Lights in HVAC Systems

UV lamps inside ductwork discourage mold growth on coils and drip pans.

✔ Control Indoor Humidity

Install whole‑house dehumidifiers or run dehumidification mode on AC systems during peak humidity.

✔ Improve Airflow

Make sure vents and returns are clear of furniture and blockage.

✔ Monitor for Early Signs

Be alert to musty odors, water stains near vents, or rust around AC units.

📌 Final Takeaways

Mold inspection in Satellite Beach — especially when AC condensation is the likely source — requires a methodical, tool‑assisted approach because moisture often hides behind surfaces and inside HVAC systems. The typical step‑by‑step process includes:

- Pre‑inspection planning

- Visual walk‑through

- Thermal imaging

- Moisture & humidity measurements

- Air quality testing

- Detailed reporting

Understanding this process helps homeowners identify problems early, justify repairs to landlords or insurance, and protect indoor air quality before mold spreads and becomes costly.

If you’d like, I can provide a printable pre‑inspection checklist you can use each season to catch AC moisture issues early — just let me know!